How To Replace An Older Hayward Filter Cartridge

Step 1

TOOLS YOU WILL NEED: 1) Hack saw 2) Plumbing record 3) Indoor-Outdoor silicon 4) Adjustable pliers with 2 gap minimum 5) Foursquare corner ruler or level vi) Magic marker seven) Medium sandpaper 8) PCV Cement nine) PVC Cleaner

Step 2

Materials you will need: one) Two PVC pipage couplings: Ane side threaded, the other side has no thread equally PVC pipe will fit into the end. Measure out INPUT and OUTPUT ports of the filter housing before purchasing. Typically information technology is either 1 1/2" or 2". Once you institute the proper size, all other PVC fabric will be the same size.

Stride three

Materials (cont'd) 2) 4 90º bending PVC couplings (photo shows 2 styles to choose from) 3) PVC pipage - you lot will have to gauge or mensurate anticipated length. An 8' length is a expert start. Buy extra, you can always return it. Brand sure the pipe is labeled "schedule 40" to handle the h2o pressure.

Step four

In this instance, we have already cut out the old filter. If you take non cut out your filter, turn off electricity going to the pump motor via your fuse box, not just the timer. You don't want the pump to turn on when you are doing this.

Step five

Accept the filter cartridge out of the housing so information technology doesn't get damaged while you work, and put the elevation back on.

Step 6

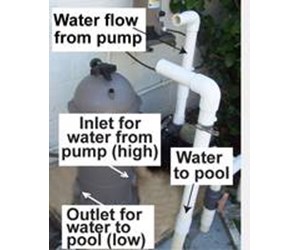

This diagram shows you the flow of your water. NOTE: There was one time a big sand filter here. Don't let the summit of the existing pipes throw you, we will trim these down.

Step 7

Put silicone into threads of filter housing and spin effectually with your finger.

Step 8

Wrap plumbers record, counterclockwise, seven – 10 times on threaded side of coupling. Install threaded couplings on both openings of housing. Use pliers to tighten. DO Non OVER-TIGHTEN.

Step 9

Now position the housing where y'all want it. In this photo, the output port (the lower of the ii) lines up direct with the existing outlet pipe to the pool. It is of import that this is aligned correctly and that the INPUT and OUTPUT PORTS are positioned properly. Remember, the output goes to the pool pipe. If you are unsure, usually there is a diagram on the front of the filter. Make sure in that location is plenty of space on both sides. Y'all want a minimum of 6" of piping extending from each outlet.

Footstep 10

Cut a section of pipe that fits into the filter output port and extend it to the pipe that leads to your pool and cut to size. Test the length and then cement into the coupling.

Step 11

At present line upwards the filter output pipe with with the pipe to the puddle, make a mark beneath the pipage with the marker and cut it so it butts upward against the pipe. The pipe volition slant down a little, lift it up to get a nice fitting. Use a corner ruler or level to ensure the pipe is straight. Cut with hacksaw blade under the pipage.

Step 12

Clean both sides of the 90º coupling. Rub the edges of the pipes a little bit with a file or sandpaper. Test the plumbing fixtures before gluing to come across if everything lines upwardly correctly.

Step 13

Then brush pipage and coupling with PVC cleaner. After cleaner has dried, cement pipes and coupling together. This completes the output connection from the filter to the puddle return pipage.

Step 14

Next we'll connect the pipe leading from the pump to the intake port of the filter housing. Cut a vi" - 8" section of pipage and cement it into the threaded coupling y'all put in earlier. Put (practise not cement) the 90º coupling at the terminate.

Step 15

Cut another piece of pipe that when sitting vertical in the coupling, extends to a higher place the motor at least 12" – 15" (y'all will trim this down later) and set into coupling. This will be your INTAKE Piping. Make sure it is straight up and down (if not, you will take problems lining up the next coupling). Now you tin cement the assembly.

Footstep 16

Go to the pump motor and cut the existing pipage extending from pump four" – 6" above the fitting. Set the 90º coupling into this pipe. Exercise Non CEMENT.

Step 17

Cut a piece of pipe that fits into the coupling and extends to the INTAKE PIPE to the filter and cutting to size.

Step 18

With a corner ruler or level, brand sure the height pipe is completely direct and level. Make a mark on the Intake Pipe and cutting to size.

Step 19

At present put the coupling in (Practise Not CEMENT) and make sure everything lines upward directly and correctly. One time you lot are confident that everything lines up, cement the whole Shebang together.

Pace 20

Requite the cement a couple of hours to set. Open the filter housing and cheque to be sure no droppings or parts from your work have fallen inside. Put the filter cartridge back in.

Pace 21

Turn on pump, and check for leaks. • Congratulations! You have simply finished a job that tin cost upwards of $100+ for a professional to install not to mention the markup on the parts

Step 22

Securing filter - It is upwardly to y'all if you want to put the filter in a stationary position. If you practise, await until the unabridged filter with pipes is done. Even so, keep in mind that bolts can rust out and it will be difficult to accept the filter off if you have to in the futurity. Typically, because of the weight of the full filter it is pretty secure.

How To Replace An Older Hayward Filter Cartridge,

Source: https://www.inyopools.com/HowToPage/how_to_replace_a_pool_cartridge_filter.aspx

Posted by: davisretraid1949.blogspot.com

0 Response to "How To Replace An Older Hayward Filter Cartridge"

Post a Comment